How to Build Coils: A Beginner's Guide

27th Aug 2025

So, you're ready to dive into the world of custom coil building. This is where vaping gets really interesting. Moving on from pre-made coils isn't just a way to save a few bucks—it’s about taking the reins and getting complete control over your vape for flavor and vapor that stock coils can't touch. Think of me as a fellow builder who's been around the block a few times, here to walk you through everything from picking your first spool of wire to that first, perfect puff.

Why Even Bother Building Your Own Coils?

Building your own coils is the ultimate way to customize your vape. You're no longer just a consumer; you become the creator, designing the very heart of your device. This hands-on approach unlocks a level of performance and satisfaction you just can't get from something mass-produced.

For most people, the journey starts with the chase for better flavor. When you select the wire and wrap it just right, you can fine-tune how it heats up and how much surface area it has. This lets you pull out specific notes in your e-liquids you might not have even known were there. It's like upgrading from standard earbuds to a high-end audio system—suddenly, all the subtle details come alive.

Taking the Driver's Seat

When you start building, you quickly realize the advantages are huge:

- Flavor on Your Terms: You can craft a build that makes your favorite dessert e-liquid richer or your go-to fruit flavor brighter and more vibrant.

- Clouds Your Way: Want a quick, intense hit or a slow, massive cloud? You control the ramp-up time and surface area to get exactly what you want.

- It's Cheaper: Let's be honest, this is a big one. A spool of wire and a bag of cotton will last you ages and cost a fraction of what you'd spend on packs of pre-made coil heads.

- A Deeper Hobby: Vaping stops being just a habit and turns into a craft. There's a real sense of accomplishment in making something with your own hands that works perfectly.

The moment it clicks is when you realize you're no longer stuck with what the shops have in stock. Your perfect vape isn't something you have to hunt for; it's something you can create yourself. That's a game-changer.

The materials you choose are obviously a huge piece of the puzzle. The wire we use is part of a massive industrial market. To give you some perspective, the aluminum sheets and coils market—a cousin in the materials world—was valued at roughly USD 52.4 billion back in 2025 and is expected to soar to nearly USD 93 billion by 2034. That's a colossal industry, and it highlights just how important it is to get your hands on high-quality wire for a consistent, safe build. If you're interested in market trends, you can find more insights on the growing materials market on gminsights.com.

In this guide, we'll cut through the confusing jargon, focus on the skills that actually matter, and hammer home the safety essentials. My goal is to make sure your first build is not just a success, but the start of a seriously rewarding part of your vaping journey. Let's get to it.

Assembling Your Coil Building Toolkit

Before you can even think about wrapping your first coil, you need to get your hands on the right gear. Just like any other craft, having the proper tools makes all the difference. It turns what could be a frustrating chore into a smooth, rewarding process. It’s not about buying every shiny gadget you see, but about building a core kit with tools that serve a specific, important purpose.

The journey always begins with the wire. Your choice of wire is the foundation of your build, influencing everything from ramp-up time to the way your e-liquid’s flavor comes through. Think of it as the star ingredient in a recipe—each type brings something unique to the final experience.

Choosing Your Wire

When you first start out, you'll likely run into three main types of wire: Kanthal (A-1), Nichrome (Ni80), and Stainless Steel (SS316L).

Kanthal is the old reliable, the true workhorse of coil building. It’s incredibly easy to work with, holds its shape beautifully, and is ideal for straightforward wattage vaping. Its ramp-up time is a bit slower, which some vapers actually prefer for a smoother, more gradual heat.

Then you have Nichrome, or Ni80. This is Kanthal's high-energy cousin. It heats up much, much faster, giving you a nearly instant vape. Many find this rapid response makes flavors feel more intense and defined. The trade-off? It’s a softer wire, so you need a lighter touch to avoid accidentally mangling your wraps.

Finally, Stainless Steel is the jack-of-all-trades. You can run it in standard wattage mode just like the others, but it also shines in temperature control (TC) mode. TC vaping is fantastic for preventing nasty dry hits because it limits the coil's maximum temperature. It's known for a very clean, crisp flavor profile and a ramp-up speed that sits nicely between Kanthal and Nichrome.

My Personal Tip: If I could give one piece of advice to a new builder, it would be this: start with a spool of 24-gauge Kanthal. It's forgiving, easy to handle, and perfect for learning the fundamentals of wrapping and pulsing before you dive into more complex materials.

To make this a little easier, I've put together a quick comparison of these common wires. It's a handy reference for seeing how they stack up at a glance.

Comparing Common Coil Building Wires

|

Wire Type |

Primary Material |

Key Characteristics |

Best For |

|

Kanthal (A-1) |

Iron-Chromium-Aluminum |

Easy to work with, holds shape well, slow ramp-up. |

Beginners, wattage mode only, consistent performance. |

|

Nichrome (Ni80) |

Nickel-Chromium |

Very fast ramp-up, intense flavor, softer wire. |

Experienced builders, wattage mode, instant vapor. |

|

Stainless Steel (SS316L) |

Steel, Chromium, Nickel |

Versatile, clean flavor, medium ramp-up. |

Wattage or Temperature Control modes, flavor chasers. |

Picking the right wire is really about matching the material to your vaping style and what you want out of your build. Don't be afraid to experiment once you've got the basics down.

The Essential Toolkit

Beyond the wire itself, a few key tools are absolutely non-negotiable, both for precision and, more importantly, for safety. Investing in a decent quality kit from the get-go will save you money and headaches in the long run.

Here are the absolute must-haves for your kit:

- A Reliable Ohm Reader: This is your most critical safety tool. You must test every single build to check for a stable resistance and ensure there are no dangerous shorts. Never, ever skip this.

- Ceramic-Tipped Tweezers: These are a game-changer for tuning your coil. Because the tips are non-conductive, you can safely pinch and strum your coil while pulsing it at a low wattage to work out any hotspots.

- Flush Cutters: You need a good pair of these to snip your coil leads as close to the atomizer posts as possible. A clean, flush cut prevents stray bits of wire from touching the atomizer cap and causing a short.

- Coiling Jig or Rod Set: Sure, you can wrap a coil around a screwdriver, but a dedicated coiling jig makes life so much easier. It guarantees every single wrap is perfectly uniform, which is the secret to a coil that heats evenly and vapes beautifully.

Getting these tools together is the first real step in your building journey. With these essentials in hand, you're setting yourself up for a safe, successful, and incredibly satisfying experience.

Wrapping Your First Perfect Coil

Alright, you've got your tools laid out. Now for the fun part—transforming a simple piece of wire into the heart of your atomizer. We're going to stick to a basic round wire coil for your first build. Mastering this is the key to building your skills and confidence before you even think about tackling the more exotic stuff. The real trick to a good coil isn't some secret technique; it's all about consistent tension and keeping your wraps nice and even.

Let me walk you through my method. I always start by snipping off a decent length of wire, usually around 6-8 inches. This gives you enough to work with and hold onto without being wasteful.

Next, grab your coiling jig or screwdriver. Pin one end of the wire firmly against the rod with your thumb—this is your anchor. Getting this starting point secure is what sets you up for a smooth, clean wrap.

The Feel of a Perfect Wrap

As you start wrapping the wire around the rod, you're looking for firm, steady pressure. You want every single wrap to sit flush against the one before it. The most common mistake I see beginners make is wrapping too loosely. That leads to gaps, which create uneven heating and those nasty "hotspots" that torch your cotton and ruin the flavor.

It all comes down to muscle memory. You need to get into a rhythm where you're pulling the wire taut with one hand while guiding it with the other. After you've done it a few times, you'll start to feel when the tension is perfect—just tight enough to hold its shape without you having to strangle the wire.

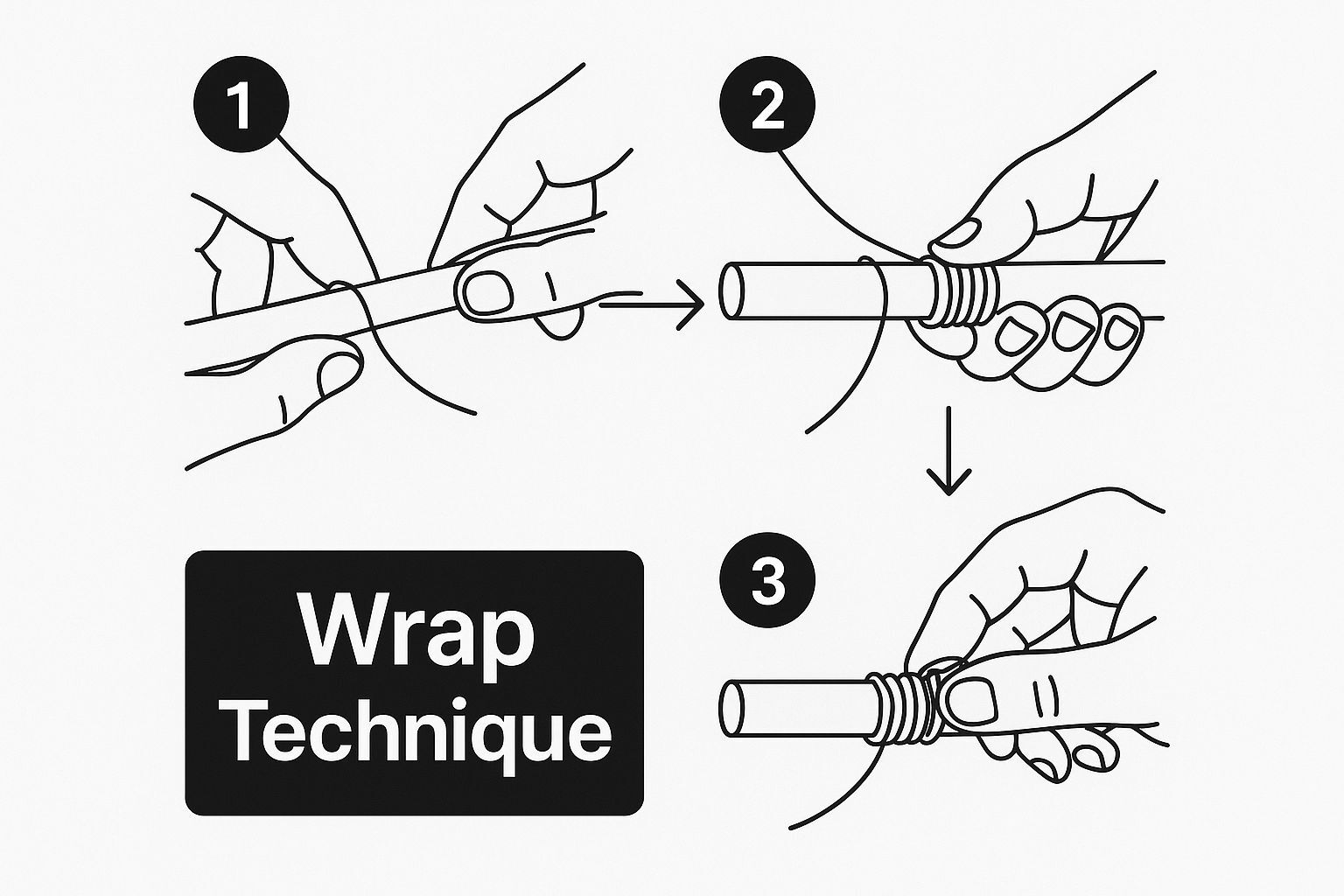

This is what that controlled pressure looks like in action.

See how the hands are working together? That's the goal. Steady hands and controlled force are what produce coils that perform like a dream.

Counting Wraps and Avoiding Pitfalls

The number of wraps you make is what determines the final resistance of your coil. A great starting point for a single-coil build is using 24-gauge Kanthal wire on a 3mm rod. If you aim for 5 to 6 wraps, you'll typically land in that sweet spot around 0.5-0.7 ohms. Just count each full circle the wire makes around the rod as one wrap.

Keep an eye out for these classic rookie mistakes while you're wrapping:

- Overlapping Wires: Make sure each new wrap settles right next to the previous one, not on top of it.

- Gaps in the Coil: Little spaces between your wraps will almost certainly cause hotspots. If you notice any, you can usually just pinch the coil together gently after you slide it off the rod.

This idea of precise winding isn't just for vaping. It’s fundamental in a surprising number of high-tech industries. Take the automotive world, for example. The ignition coils market is massive, projected to grow from USD 14.82 billion in 2025 to over USD 20.03 billion by 2032. For those parts, perfect winding is everything. It's a cool reminder that the basic skills you're learning here have applications far beyond our hobby. You can discover more about these industrial coil applications on coherentmarketinsights.com.

Once you've finished your last wrap, gently slide the coil off the jig. You should now be holding a neat little coil with two "legs" sticking out. That's it! You've officially built your first coil and are ready to get it installed and tested.

Getting Your New Coil Installed and Tested

You’ve got a perfectly wrapped coil sitting on your workbench. Nice work. Now for the fun part: getting it installed in your atomizer and bringing it to life. This is where precision really counts. A little bit of care here is what separates a fantastic vape from a frustrating headache, or worse, a safety issue. Let's get that coil mounted, tested, and glowing perfectly.

The first move is to get your coil situated in your RDA or RTA. You'll want to carefully guide the two wire "legs" into the post holes on your build deck. I always use my coiling rod to help position the coil right where I want it—usually centered over the airflow. You need to make sure it’s not touching the deck, the posts, or the inside of the top cap. Proper placement is everything; it’s how you get that sweet spot of airflow for amazing flavor and vapor.

Locking it Down and Checking for Problems

Once you've got the coil sitting pretty, go ahead and gently tighten down the post screws. Don't crank on them, just snug them up so the leads are secure. Now, grab your flush cutters and snip off the excess wire as close to the posts as you possibly can. Any little bit of stray wire left sticking out could touch the chamber and cause a dangerous short circuit.

This next part is the most important step in the entire process. Screw your atomizer onto a dedicated ohm reader or a regulated mod you trust to give you an accurate reading.

- Look for Shorts: The screen should show a stable resistance value. If you see 0.00 ohms or the numbers are jumping all over the place, you have a short. Don't even think about firing it. Take it apart and figure out where the coil is touching something it shouldn't be.

- Verify the Resistance: The number on the screen should be pretty close to what you were aiming for. A tiny bit of variation is totally normal, but if it's way off, something’s not right. Double-check that your post screws are tight and that you didn't miscount your wraps.

Seriously, don't skip the testing. This is your safety check. A solid, stable resistance reading is the green light that tells you the build is safe and ready for the final tune-up.

Pulsing the Coil to Perfection

Okay, your ohm reader gave you a stable reading. Now it's time to get rid of any hotspots. Pop your atomizer onto a regulated mod and set the power way down—I usually start around 15-20 watts.

Gently pulse the fire button for just a second or two. You'll see the coil begin to glow. More often than not, it won't glow evenly at first. You'll see bright spots flare up before the rest of the coil—those are hotspots, and they'll give you a nasty, harsh vape.

To fix them, let go of the fire button and grab your ceramic-tipped tweezers. Gently strum the coil like it’s a tiny guitar string. Sometimes, a light pinch is all it needs. Be sure you’re not firing the mod while the tweezers are touching the coil!

Keep repeating this little dance—pulse, release, strum—until the coil glows beautifully and evenly, starting from the very center and spreading outwards. That perfect, uniform glow is the sign of a job well done. It means the heat is spreading exactly as it should, which is the key to unlocking incredible, consistent flavor.

Mastering the Art of Wicking

Here's where everything comes together. You can wrap a flawless, beautiful coil, but if the wicking is off, it’s just a fancy little heater. The wick is what turns that coil into a flavor engine by delivering e-liquid exactly where it needs to go.

Nail the wicking, and you’re rewarded with rich, saturated flavor. Get it wrong, and you’re looking at either a muted, disappointing vape or, worse, the nasty, harsh surprise of a dry hit. It’s an art that’s as much about feel as it is about following steps.

Finding the Right Wicking Material and Technique

You'll almost always be using cotton, but not all cotton is the same. Most experienced builders gravitate toward specific types, like Japanese organic cotton pads or popular brands like Cotton Bacon. They're prized for being clean, incredibly absorbent, and free of the impurities that can mess with your flavor.

A technique I’ve had a lot of success with is the "Scottish Roll." It sounds a bit odd, but it works wonders. You take a sheet of Japanese cotton, gently peel away the thin, compressed layers on the top and bottom, and then carefully stretch the whole thing out. From there, you roll it into a surprisingly springy tube. This creates a wick that's both dense and airy, giving it an amazing capacity for juice and fantastic flow.

The real secret is getting the tension just right as you pull the wick through the coil. It should feel snug and offer some resistance, but it shouldn't be so tight that you end up bending or moving the coil itself. Imagine threading a large needle—it glides through, it's not forced.

If your wick is too loose, you'll have air gaps that can't carry liquid efficiently, leading to hot spots. If it's too tight, you’re basically choking off the juice supply. It takes a few tries to develop a feel for it, but once you do, you'll know that perfect resistance instantly.

Trimming and Priming for Perfect Performance

After threading the cotton through your coil, you need to trim the "tails." The right length depends entirely on your specific atomizer, and this is probably the most device-dependent part of the whole process.

- For RDAs (Drippers): As a rule of thumb, you want to trim the tails so they just brush the bottom of the juice well. This lets them soak up every last drop of e-liquid you add.

- For RTAs (Tanks): This requires a bit more finesse. The goal is to trim the tails so they fit neatly into the wicking channels without being packed in too tightly. I always take a second to fluff up the ends, as this helps them absorb liquid much more effectively from the tank's reservoir.

It’s interesting how engineering principles apply even on this tiny scale. In massive industrial systems, like the global cooling coils market—valued at USD 4.776 billion back in 2025—engineers meticulously design fin placement to maximize thermal efficiency. In the same way, how you place your wick tails directly controls the liquid flow and heat exchange in your vape coil. You can actually explore the cooling coils market report on cognitivemarketresearch.com for a look at the bigger picture.

Finally, the most important step before you fire it up: priming. Drip your e-liquid directly onto the coil and cotton until it’s completely saturated and can't absorb any more. This simple action ensures your first puff is vaporizing liquid, not burning dry cotton. It’s the final touch that unlocks incredible flavor from the very beginning.

Wrapping It Up: Your Journey as a Builder

Congratulations on building your first coil! You’ve just unlocked a completely different side of vaping, one where you have total control over the flavor and performance. This is where the real fun begins, moving beyond what off-the-shelf coils can offer.

Keep in mind that coil building is a skill, and like any craft, it gets better with practice. Your first few coils might not be perfect, and that’s completely okay. Every single person who builds their own coils started right where you are now. Trust the process.

The most rewarding part of this isn't just the better flavor—it's knowing you created it. The perfect vape isn't something you buy; it's something you build with your own hands.

Don't be afraid to experiment. Try out different wire types, play with the number of wraps, and see how different wicking techniques change your experience. The vaping community is full of builders happy to share what they’ve learned, so jump into forums and groups with your questions.

Now, go enjoy the fantastic vape you just built. You earned it.

Nicotine is an addictive chemical. Content intended for adults 21+.

Got Questions? We've Got Answers.

Every builder, no matter how experienced, runs into a snag now and then. When I first started, I spent half my time scratching my head over these exact issues. Let's walk through some of the most common hurdles you might face so you can build with confidence.

Troubleshooting Your Build

Why is my resistance reading way off?

If your ohm reader is giving you a number that looks totally wrong, it’s almost always one of two culprits.

A resistance that’s too high usually signals a poor connection. Your coil leads probably aren't clamped down tight enough in the atomizer posts. Just give those post screws a gentle turn to make sure everything is snug and secure.

On the other hand, a resistance that’s way too low—or one that jumps down to zero—is a serious warning sign. This means you have a short circuit. Your coil is touching something it shouldn't be, like the build deck, a post, or the inside of the top cap. You absolutely have to fix this before you fire the mod. Take a close look and reposition the coil so it’s floating freely with no metal contact.

What are these 'hotspots' I keep hearing about?

Hotspots are small, angry red sections of your coil that glow much brighter and hotter than the rest. They're the number one cause of that nasty, burnt taste because they torch your cotton and flash-vaporize e-liquid in one tiny spot.

Fixing them is a rite of passage. Start by pulsing your coil at a very low wattage, just enough to get it glowing faintly. Let go of the fire button, then use your ceramic tweezers to gently strum the coil like a guitar string or give it a light pinch. Pulse, strum, repeat. You’ll see the glow become more uniform.

A coil that glows evenly from the center outwards is the mark of a great build. That smooth, even heat is the secret to getting rich, consistent flavor without any harsh surprises.

How much cotton is the right amount of cotton?

Ah, the classic wicking dilemma. Getting this right is more of an art than a science, and it’s something you’ll get a feel for over time.

You're aiming for a snug fit. As you pull your cotton through the coil, you should feel some gentle resistance, but not so much that you have to yank it and risk bending your perfectly wrapped coil.

- Too loose? You'll get dry hits because the wick can't draw up enough e-liquid to keep up.

- Too tight? You'll choke off the juice flow, leading to muted, disappointing flavor.

Think "snug, not strangled." You'll know you've nailed it when there's just a bit of friction as it slides through.

Ready to put this all into practice? Inline Vape has all the wire, cotton, and top-notch tools you need to jumpstart your building journey. Check out our huge selection of RBA supplies and grab everything for your next perfect build at https://www.inlinevape.com.

Nicotine is an addictive chemical. Content intended for adults 21+.